01 Sep 2022

HKU Chemists Develop a Novel Laser-Assisted Method to Make Catalysts for Efficient Oxidation of Glycerol from Biodiesel into Fine Chemicals

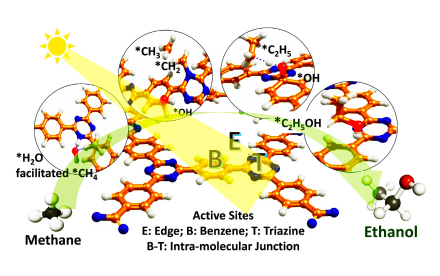

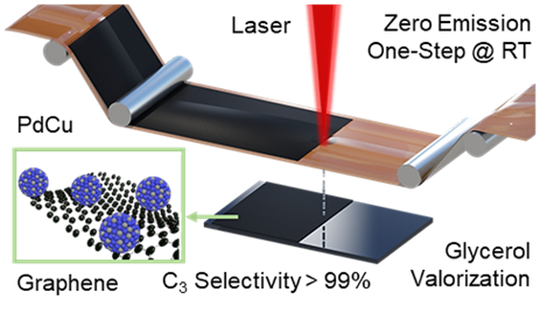

Schematic of a scalable, toxic-emission-free method using LANP to upcycle excess glycerol into hydrocarbon commodities with bimetallic nanoconstructs on graphene. Image adapted from ACS Nano, 2022, doi:10.1021/acsnano.2c02865.

A research team led by Dr Edmund CM TSE from HKU Department of Chemistry developed an effective laser-assisted nanomaterial preparation (LANP) technique to generate bimetallic nanomaterials as integrated electrodes for glycerol oxidation.

In biodiesel manufacturing, every 100 kg of biodiesel generates 10 kg of crude glycerol as a byproduct. Having a great potential in green energy and value-added products, the excess byproduct glycerol provides an opportunity to realize the 'Waste-to-Treasure' concept. Glycerol can be used to make renewable fuels with energy density comparable to that of ethanol; glycerol can also be converted into valuable products, ranging from pharmaceutical and agricultural precursors to feedstock and fine chemicals via electrocatalytic glycerol oxidation reaction (GOR).

'Glycerol can be oxidized into formic acid, which can be used in fuel cells, or into compounds with three carbons (C3) like glyceric acid, tartronic acid, dihydroxyacetone, and glyceraldehyde, which have various industrial uses.' Dr Xiaoyong MO, the first author of this paper, provided her thoughts on the challenges associated with glycerol upcycling. 'However, it is difficult to precisely control the selectivity of C3 products in GOR. Even though high temperature allows multiple products to be synthesised simultaneously, the product selectivity is poor because some desired products are unstable at elevated temperatures.'

Thermal catalysis and room-temperature electrocatalysis have both been explored as solutions to this problem. However, both have their disadvantages. Thermal catalysis necessitates large-scale facilities devoted to harsh reaction conditions and excess chemical oxidants. Although electrocatalysis can be done at room temperature and pressure, the catalysts are typically prepared in extreme environments and generate a significant quantity of liquid waste. This procedure entails high initial and ongoing expenses as well as raising health and safety concerns.

To tackle the problems, the Tse group recently developed a scalable LANP method to generate room-temperature electrocatalysts for GOR that can work in an environmentally begin fashion without discharging toxic liquid waste. Moreover, by fine-tuning the laser parameters, this novel method can produce dual-metal nanomaterials with tunable physical properties and chemical compositions for controllable selectivity towards C3 synthesis. As proof of concept, palladium and copper are used to make the catalyst. The addition of copper to palladium addresses surface poisoning issues by making the surface active towards GOR and thus preventing reaction kinetics from slowing down.

'This novel LANP technology can be considered as a 3D printing machine for metals. Figuratively, the laser can be viewed as the nozzle, while the polyimide-palladium-copper source is like the filament.' Dr Edmund Tse, the lead principal investigator of this work, compared the laser fabrication technique to 3D printing. 'During LANP, a laser is irradiated on the back side of the source, and metal nanoparticles are transferred together with the polyimide onto a substrate in a programmable manner with a predesigned 2D pattern. The height of the catalyst substrate is then determined by the number of layers transferred from the polyimide-metal source.'

Compared with the state-of-the-art catalysts, this new catalyst exhibits an exceptional overall selectivity of 99% for total C3 products, which is two times higher than that realized on a conventional platinum catalyst. Moreover, compared to traditional catalysts, the post-heat-treated catalyst is three times more selective for glyceric acid, which can be used in skin therapy. In short, this LANP approach developed at the HKU-CAS Joint Laboratory on New Materials in collaboration with Dr Heng-Liang Wu from National Taiwan University can be used to create active, selective, and long-lasting multimetallic nanocatalysts that can facilitate processes important for renewable energy schemes.

Journal title: 'Direct 3D Printing of Binder-Free Bimetallic Nanomaterials as Integrated Electrodes for Glycerol Oxidation with High Selectivity for Valuable C3 Products' (ACS Nano, 2022)

The journal paper can be accessed here.

Click hereto learn more about the research group of Dr Edmund CM Tse.

Click here to learn more about HKU-CAS Joint Laboratory on New Materials.