08 May 2024

Go 100% Green with Solar Energy and Biomass

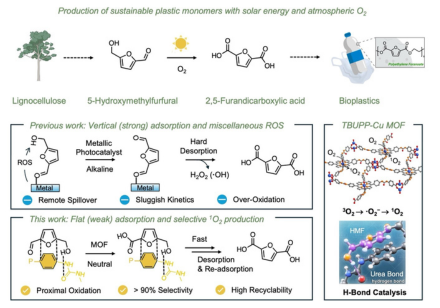

In this latest research, we have made significant advancements in the field of harnessing solar energy and biomass, resulting in the production of green chemicals and plastics.

In the global pursuit of achieving ‘Net-Zero’ chemical and material manufacturing, there are two abundant but under-used resources: solar energy and biomass, particularly in Hong Kong.

In a recent publication in Angewandte Chemie International Edition, a team led by Professor Zhengxiao GUO from HKU Department of Chemistry and its collaborators, have developed a Cu(II) porphyrin framework photocatalyst that effectively harnesses solar energy to upgrade a biomass derivative, HMF (5-hydroxylmethylfurfural), into a key sustainable ingredient, FDCA (2,5-furandicarboxylic acid), e.g. to make polyethylene furanoate (PEF) as a renewable alternative to polyethylene terephthalate (PET).

This breakthrough opens pathways towards the production of 100% environmentally friendly chemicals and materials, potentially revolutionising the field of bio-plastics and resins.

In the past, this conversion process faced limitation due to poor selectivity and sluggish kinetics, mainly caused by the vertical coordination of HMF at relatively strong catalyst sites. To overcome this, the team purposely designed and inserted side-chain incorporated urea linkages to the ‘traditional’ Cu(II) porphyrin framework catalyst. As a result, the newly formed TBUPP-Cu MOF catalyst which alters the interaction of HMF by weakening the hydrogen bond at the urea site and promoting a flat adsorption mode via π–π stacking with the benzene moiety.

The unique configuration facilitates the approach of the –CHO group of HMF to the photo-excited porphyrin ring, leading to the formation of kinetically and thermodynamically favourable intermediates and subsequent desorption. Through charge localisation and orbital energy alignment, the catalyst enables selective activation of O2 over the porphyrin, generating ·O2− and 1O2, instead of highly oxidative H2O2 and ·OH, via a ‘spin-flip’ electron transfer mechanism, which drives the ambient partial oxidation of the proximal –CHO.

The effective utilisation of the redox species and the circumvented over-oxidation facilitate a FDCA selectivity over 90% and a high turnover number of 193 mole_HMF /mole_Cu. The facile production of high-purity FDCA, zero-waste recovery of intermediates and high durability feature the TBUPP-Cu MOF catalyst a promising photo-oxidation platform towards net-zero biorefining and sustainable manufacturing.

Click here to view the journal paper.